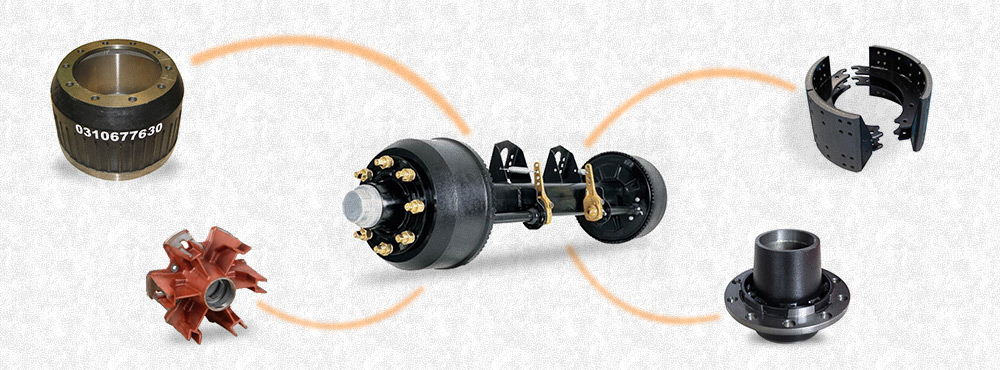

CATEGORIES

LEAF SPRING

Composite Leaf Springs will Replace Steel Leaf Springs in the Future

Composite Leaf Springs will Replace Steel Leaf Springs in the Future

Recently, someone released a picture of a lightweight semi-trailer in the car group. This trailer actually uses a "plastic leaf spring" suspension? One stone hit a thousand waves, and a discussion about "plastic leaf springs" exploded.

Everyone is generally full of doubts about this new "plastic leaf spring", can a plastic-like leaf spring carry dozens of tons of weight? Can it last for a year under overload and bad road conditions? Isn't this a lie?

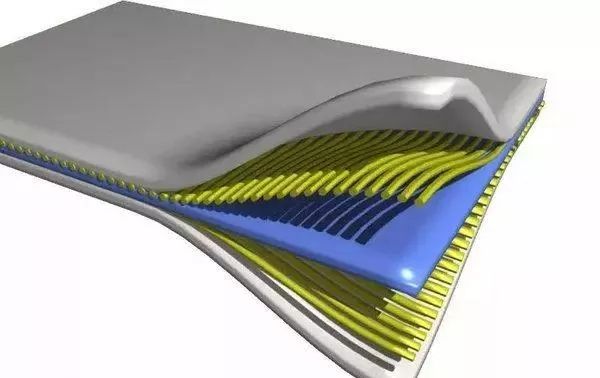

In fact, it is not plastic. Its scientific name is: "Polyurethane matrix resin glass fiber reinforced leaf spring". The main components of this composite material include reinforcing fiber and resin matrix, which are then processed and synthesized through a certain process (RTM).

In addition, in some foreign light-weight heavy trucks and buses, composite leaf spring structures have also begun to be adopted.

There are many advantages, and it is expected to replace steel leaf springs in the future

At present, major automobile manufacturers and supporting manufacturers have begun to conduct research on this composite leaf spring. Many pioneers can't wait to popularize it into mass-produced products. So what are the benefits of this composite leaf spring?

Generally, the total weight of composite leaf spring (including metal joint) is about 50% of the weight of leaf spring, which can greatly reduce the weight of suspension and save fuel consumption.

For heavy trucks, this weight reduction effect is more simple than aluminum alloy fuel tank and aluminum alloy wheels. If the whole vehicle is replaced with composite leaf springs, it can reduce the weight of more than a ton, which means that more goods can be loaded and more fuel oil can be saved.

Second, better shock absorption performance

This material was developed jointly by Henkel and Benteler SGL. It has two characteristics: light weight and good performance. It is said that a composite leaf spring is 65% lighter than the traditional steel leaf spring.

Not a new thing, it has been used in passenger car

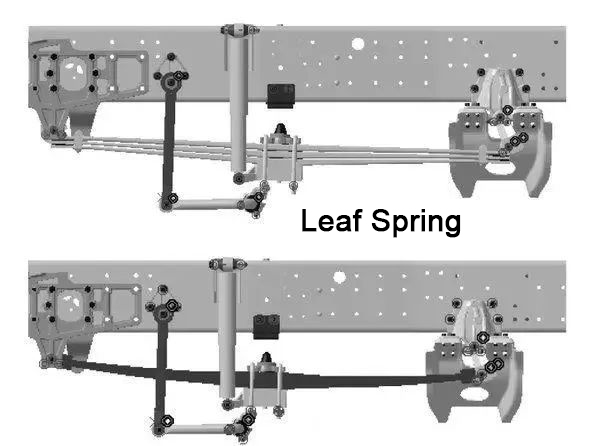

Although it is rarely seen in commercial vehicles, this material has been widely used in the automotive field. This composite leaf spring has been used in the latest Volvo XC60 chassis suspension.

The green structure in the picture above is the horizontal glass fiber reinforced composite leaf spring used in the Volvo XC60. It is made of glass fiber (provided by Benteler) and polyurethane (provided by Henkel).

The traditional leaf spring commonly used in heavy trucks has a small stroke and poor comfort, and the traditional leaf spring will produce a certain abnormal noise due to the friction between the spring leaves.

For the composite leaf spring, the load distribution is uniform, and its own damping characteristics can also accelerate the attenuation of vibration and provide passengers with good ride comfort. In addition, composite leaf spring generally adopts single spring structure, so there will be no abnormal sound problem.

Third, better durability

The composite leaf spring has a very high stress intensity coefficient, that is, high toughness. Under load, the higher the toughness, the better the fatigue resistance. During driving, the automobile leaf spring always bears dynamic load. The flexible material has high fatigue resistance, which can greatly prolong the service life of these parts.

According to the experimental statistics, the fatigue life of the traditional leaf spring is about 100000 times, while the fatigue life of the composite leaf spring is more than twice that of the ordinary multi leaf spring, greatly reducing the user's use and maintenance cost. In addition, it has the characteristics of safe fracture and can improve the reliability of the vehicle.

Source: Truck channel