CATEGORIES

- Semi Trailer

- Leaf Spring

- Agricultural Trailer Drawbar Leaf Spring

- Toyota Leaf Spring

- Volvo Leaf Spring

- Hyundai Leaf Spring

- Man Leaf Spring

- KIA Leaf Spring

- Scania Leaf Spring

- Nissan Leaf Spring

- TRA Leaf Spring

- Hino Leaf Spring

- Isuzu Leaf Spring

- BPW Leaf Spring

- BENZ Leaf Spring

- Nissan Leaf Spring

- ROR Leaf Spring

- Mitsubishi Leaf Spring

- Trailer Leaf Spring

- Parabolic Leaf Springs

- Boat Trailer Leaf Spring

- Z Type Leaf Spring

- Mercedes Benz Leaf Spring

- Small Leaf Spring

- Coil Spring

- Trailer Spring in North America Picture

- Trailer Spring in North America Catalogue

- Semi Finished Leaf Spring

- ROCKER ROLLERS

- OFF ROAD SPRINGS

- EYE TO EYE SPRINGS

- SLIPPER SPRINGS

- Bolt

- Trailer Turntable

- Brake Drum & Hub

- Wheel Rim

- Landing Gear

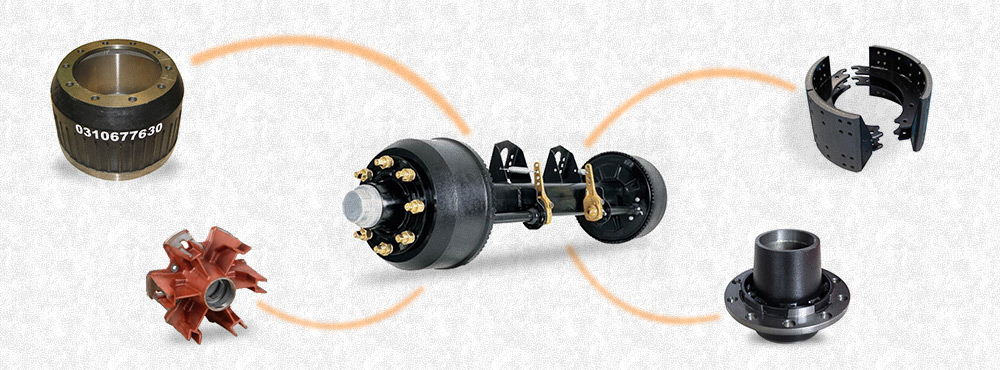

- Axle and parts

- Mechanical Suspension and parts

- Air Suspension

- Bogie

- Fifth Wheel & King pin

- Air Bag

- Slack adjuster

- Air chamber

- Twist Lock

- Mudguard

- Flat Bar

- LED Lamp

- Other parts

- Agricultural Machinery parts

- Trailer parts

CONTACT US

Tel:+86-592 5745970

Tel:+86-592 5745970 Mobile:+8618059238601

Mobile:+8618059238601 Whatsapp:+8618059238601

Whatsapp:+8618059238601 Wechat:+8618059238601

Wechat:+8618059238601 Email:market@wondee.com

Email:market@wondee.com

PRODUCTS

- China

- WONDEE

- Tianjian, Xiamen

- About 7 ~ 20 Working Days

- L/C, T/T, Western Union

- Product Details

WONDEE leaf spring factory was found in 2002. Whe have 4 branch plants, 13 production lines and

1 international marketing center with an annual output 200,000 tons. We have passed ISO/TS16949 certificate in 2006.

Before Heat Treatment Leaf Spring Detail Photos:

Information for Semi finished Leaf Spring

|

||

No. |

Leaf spring Series |

The Advantages for leaf spring factory |

1 |

Raw material |

6M or 5.8M |

2 |

Cutting length raw material |

1.Reducing raw material inventory for low volume less-use special size 2.Zero waste of raw material3.Save some production line managerment costs and machine cost |

3 |

Semi-finished leaf spring (with eyes, camber, end cutting or parabolic) |

1.Save the model developed costs if new type 3.Ensure the heat treatement temperature and surface treatment is same as this treatment is do in own production line |

4 |

Loose Leaf Spring |

1.Sell directly for after-market 2.Make it assembly in own production line and print own logo (or we do for you) |

5 |

Complete leaf spring assembly (Conventional & Parabolic) |

1.Sell directly for your customers as own products 2.Made the leaf spring series bigger and variety, to satisfy customers asking. |

6 |

Bolt (Center bolt, wheel bolt, U-bolt), Bush |

|

Curtting Flat Bar Value & benefits to the customers

1) Length can be custom built, such as 1.8M,1.9M,2M,2.3M or other length as per customers' demand.

2) Special section size available, width from 40mm to 160mm, thickness from 5mm to 59mm.

3) Further process decided by customer, just tell us the section size and cutting length with quantity, we supply the cutting flat bar, customer do the following process.

After eye Forning

After ear Forming

After Rolling

Before Painting

CONTACT

|

|

|

Ms Sunny Yang |

|

+86 138 6049 3379 |

|

|

|

|