CATEGORIES

- Semi Trailer

- Leaf Spring

- Agricultural Trailer Drawbar Leaf Spring

- Toyota Leaf Spring

- Volvo Leaf Spring

- Hyundai Leaf Spring

- Man Leaf Spring

- KIA Leaf Spring

- Scania Leaf Spring

- Nissan Leaf Spring

- TRA Leaf Spring

- Hino Leaf Spring

- Isuzu Leaf Spring

- BPW Leaf Spring

- BENZ Leaf Spring

- Nissan Leaf Spring

- ROR Leaf Spring

- Mitsubishi Leaf Spring

- Trailer Leaf Spring

- Parabolic Leaf Springs

- Boat Trailer Leaf Spring

- Z Type Leaf Spring

- Mercedes Benz Leaf Spring

- Small Leaf Spring

- Coil Spring

- Trailer Spring in North America Picture

- Trailer Spring in North America Catalogue

- Semi Finished Leaf Spring

- ROCKER ROLLERS

- OFF ROAD SPRINGS

- EYE TO EYE SPRINGS

- SLIPPER SPRINGS

- Bolt

- Trailer Turntable

- Brake Drum & Hub

- Wheel Rim

- Landing Gear

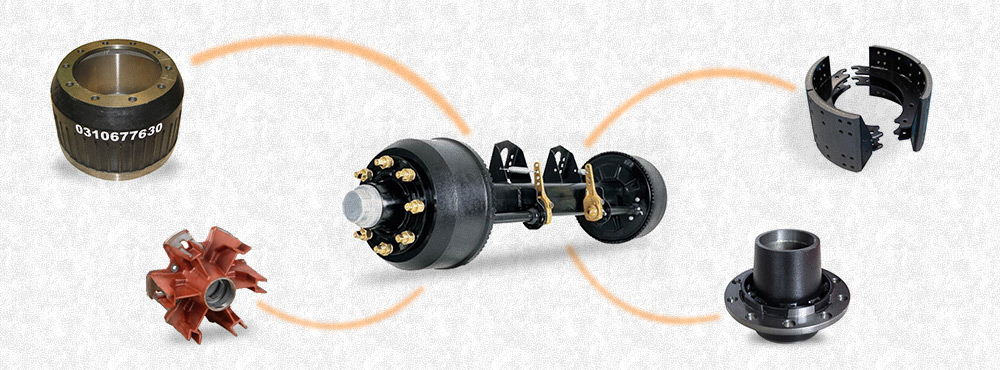

- Axle and parts

- Mechanical Suspension and parts

- Air Suspension

- Bogie

- Fifth Wheel & King pin

- Air Bag

- Slack adjuster

- Air chamber

- Twist Lock

- Mudguard

- Flat Bar

- LED Lamp

- Other parts

- Agricultural Machinery parts

- Trailer parts

CONTACT US

Tel:+86-592 5745970

Tel:+86-592 5745970 Mobile:+8618059238601

Mobile:+8618059238601 Whatsapp:+8618059238601

Whatsapp:+8618059238601 Wechat:+8618059238601

Wechat:+8618059238601 Email:market@wondee.com

Email:market@wondee.com

PRODUCTS

Trailer Suspension TRA2705 Leaf Spring

- China

- WONDEE

- 751-05

- TRA2705

- Trailer

- Tianjin, Xiamen, Shenzhen

- About 20 Working Days

- L/C, T/T, Western Union

- Product Details

TRA2705 Leaf Spring Dimension:

1.Size: 75 x 13

2. Senven Leaves, Conventional type

3. OEM No.: TRA2705, 751-05

4. Weight: 44.83KG

Trailer Suspension TRA2705 Leaf Spring are made as follows:

Multi-leaf springs are made as follows:

1. Shearing of flatbar

2. Center holepunching / Drilling

3. End Heatingprocess forming (hot & cold process)

1. Eye Forming /Wrapper Forming

2. Diamond cutting/ end trimming / width cutting / end tapering

3. End punching /end grooving / end bending / end forging / eye grinding / end rolling

4. Center holepunching / Drilling / nibbing

4. Heat Treatment

1. Heating

2. Hardening

3. Cambering

4. Quenching

5. Tempering

5. Surfacepreparation

1. Shot peening /stress peening

2. Primary painting

6. Eye bushpreparation process

1. Eye reaming /eye boring

2. Bush insertion

3. Bush reaming

7. Assemble

1. Presetting &load testing

2. Finish painting

3. Marking &packing