CATEGORIES

- Semi Trailer

- Leaf Spring

- Agricultural Trailer Drawbar Leaf Spring

- Toyota Leaf Spring

- Volvo Leaf Spring

- Hyundai Leaf Spring

- Man Leaf Spring

- KIA Leaf Spring

- Scania Leaf Spring

- Nissan Leaf Spring

- TRA Leaf Spring

- Hino Leaf Spring

- Isuzu Leaf Spring

- BPW Leaf Spring

- BENZ Leaf Spring

- Nissan Leaf Spring

- ROR Leaf Spring

- Mitsubishi Leaf Spring

- Trailer Leaf Spring

- Parabolic Leaf Springs

- Boat Trailer Leaf Spring

- Z Type Leaf Spring

- Mercedes Benz Leaf Spring

- Small Leaf Spring

- Coil Spring

- Trailer Spring in North America Picture

- Trailer Spring in North America Catalogue

- Semi Finished Leaf Spring

- ROCKER ROLLERS

- OFF ROAD SPRINGS

- EYE TO EYE SPRINGS

- SLIPPER SPRINGS

- Bolt

- Trailer Turntable

- Brake Drum & Hub

- Wheel Rim

- Landing Gear

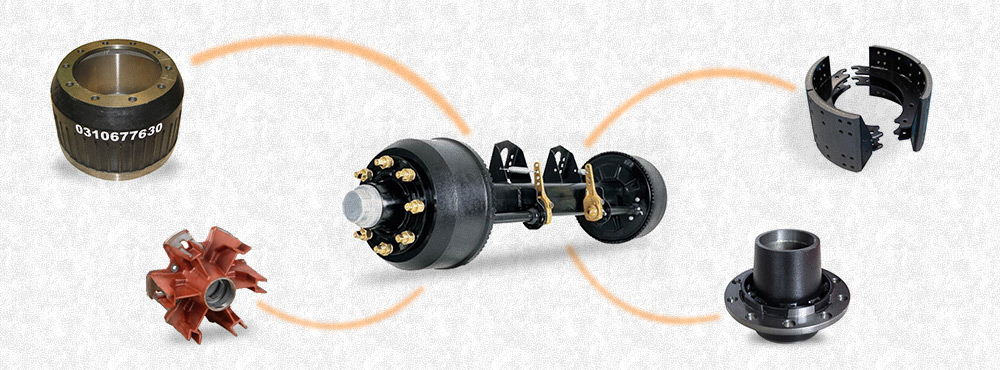

- Axle and parts

- Mechanical Suspension and parts

- Air Suspension

- Bogie

- Fifth Wheel & King pin

- Air Bag

- Slack adjuster

- Air chamber

- Twist Lock

- Mudguard

- Flat Bar

- LED Lamp

- Other parts

- Agricultural Machinery parts

- Trailer parts

CONTACT US

Tel:+86-592 5745970

Tel:+86-592 5745970 Mobile:+8618059238601

Mobile:+8618059238601 Whatsapp:+8618059238601

Whatsapp:+8618059238601 Wechat:+8618059238601

Wechat:+8618059238601 Email:market@wondee.com

Email:market@wondee.com

WONDEE New painting line for leaf spring - - Surface treatment like Wheel Rim

2016-08-19 15:24:52

WONDEE New painting line for leaf spring (Surface treatment like Wheel Rim), let you feel the same OEM quality for competitive price.-----------------WONDEE GROUP

We use electrophoretic painting for single spring electrostatic painting for leaf spring assembling, this way make leaf spring appearance very very nice. In China, we are unique factory for this technology. By this way, we got many repeat orders from our clients and our clients are excited and very satisfied.

Process:

Part-1: Perfect painting.We use electrophoretic painting for single spring electrostatic painting for leaf spring assembling, this way make leaf spring appearance very very nice. In China, we are unique factory for this technology. By this way, we got many repeat orders from our clients and our clients are excited and very satisfied.

Part-2: Salt spray testing reach 500 hours.

This guarantee is able to avoid rusting problem completely. Genera industrial level is 150~200 hours, we have a obvious advantage.

Part-3: Pre short-peening.

We make short peening under rated capacity, by this technology, our leaf spring is able to passed 180,000 times fatigue life, and average Chinese level is 150,000 times.

Part-4: Pre-pressing and adjust.

This process is used for OEM quality, but our factory used every order. This method ensure leaf spring reasonable camber and customers will not complaint camber problem at all.